BEER DISPENSING EQUIPMENT

FOUNTS

PARTS

SAFETY

WASH OUTS

Air Compressor

Gas Equipment

DRIP TRAYS

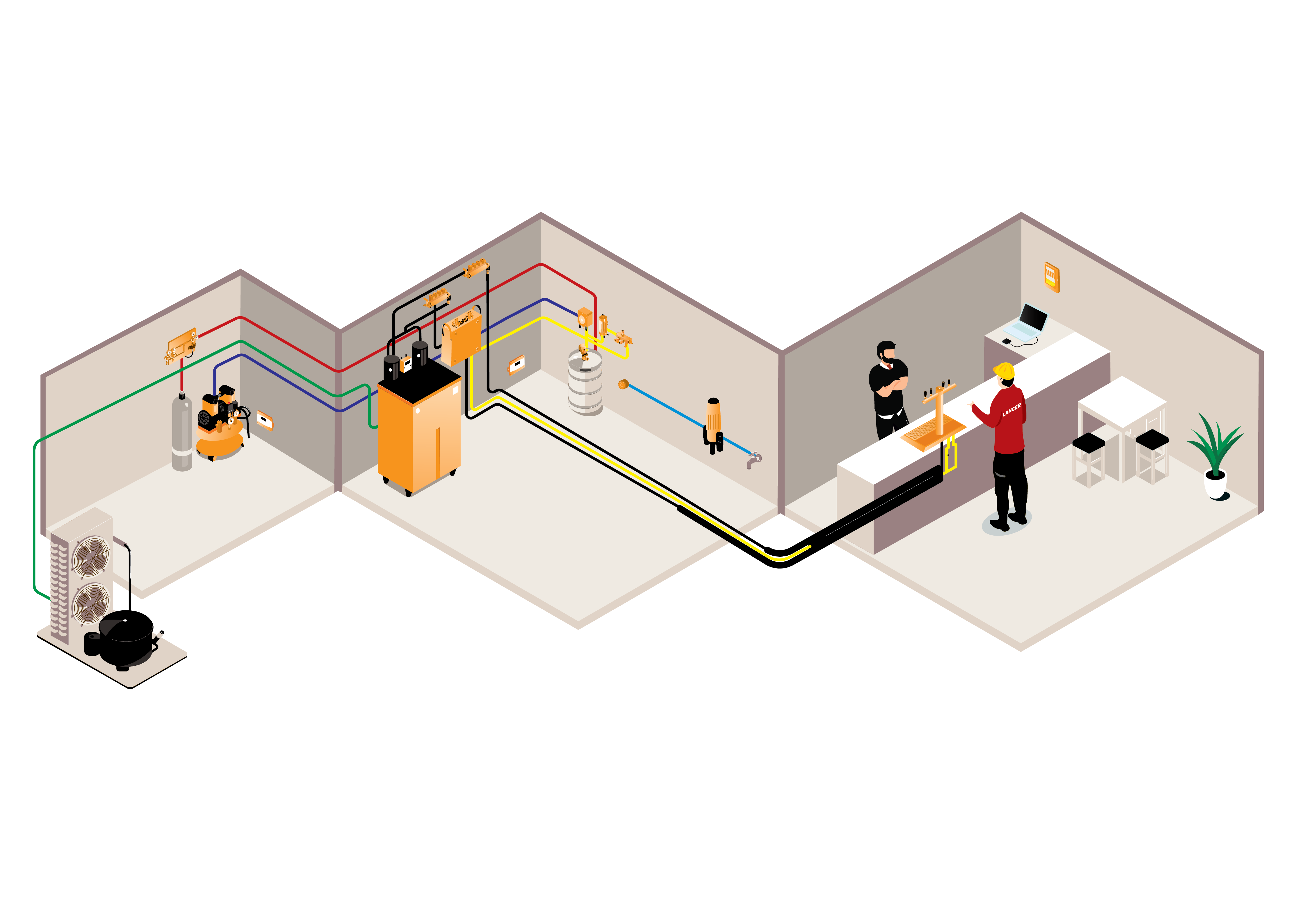

PYTHON

SOFT DRINK DISPENSING EQUIPMENT

TOWERS

CED - Counter top Unit

SUPERCHILLERS

AIR COMPRESSOR

PYTHON

SAFETY

DropIn – Incounter Unit

VALVES

ICE BEVERAGE DISPENSER (IBD)

SOFT DRINK DRIP TRAY

Gas Equipment

FROZEN BEVERAGE DISPENSING EQUIPMENT

Frozen Carbonated Beverage Dispensor

Frozen Non-Carbonated Beverage

WATER FILTERS

SAFETY

TROLLEYS

PUMPS

Gas Equipment

-

ProductsINDUSTRY LEADER IN FROZEN BEVERAGES MACHINES

-

WORLD OF LANCERMain Menu

-

Main Menu